Our 2021 Sustainability Report

Established in 1971, LOG has spent more than 50 years building a fair, ethical, innovative, reliable, professional, caring business with strong foundations in the community and in the society in which it operates.

As a privately owned, profitable and constantly growing company, LOG has the opportunity to make a positive impact on the world. For that end, we pursue sustainable action while engaging all of our stakeholders to make a difference – together. This will ensure the continuation of our activities, prosperity and business resilience of our employees, partners and the society for many years to come.

LOG seeks to promote sustainability in order to meet its stakeholder’s expectations, adapt itself to the urgent need to promote environmental and social solutions and take active part together with the global business sector for future generations.

We invite you to read our 2021 Sustainability Report and get to know our work in all the key pillars of the sustainability strategy – our planet, our employees, our supply chain and our business conduct.

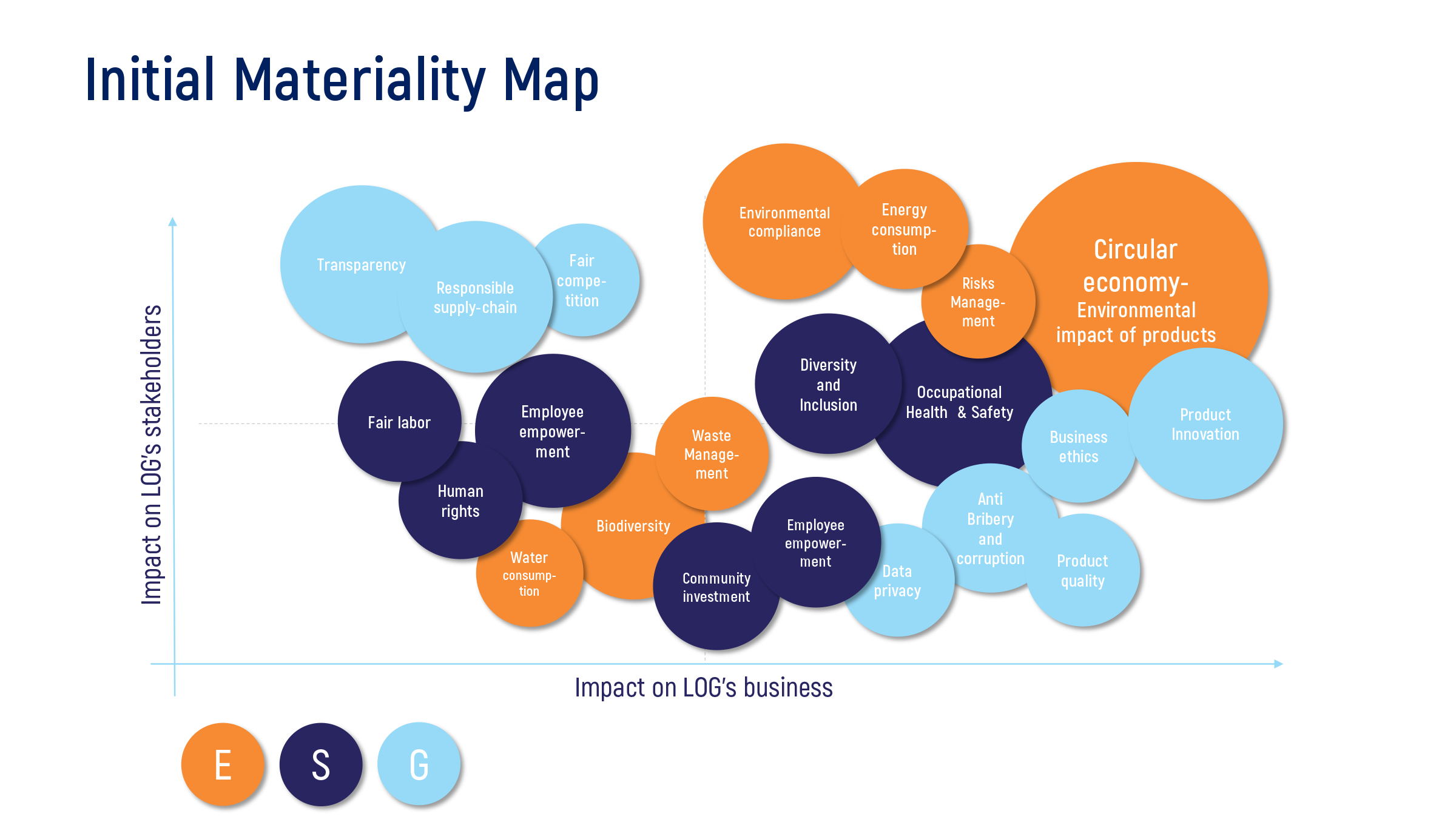

Our sustainability strategy is based on an ongoing and ongoing dialogue with our key stakeholders:

This dialogue helped us recognize the expectations of our stakeholders along with examining industry practices, analyzing SASB-focused topics and analyzing the global urgency to promote environmental sustainability – we have come to understand that the key sustainability issues we need to prioritize are the environmental issues – were can have a positive impact on our business, our people and our environment.

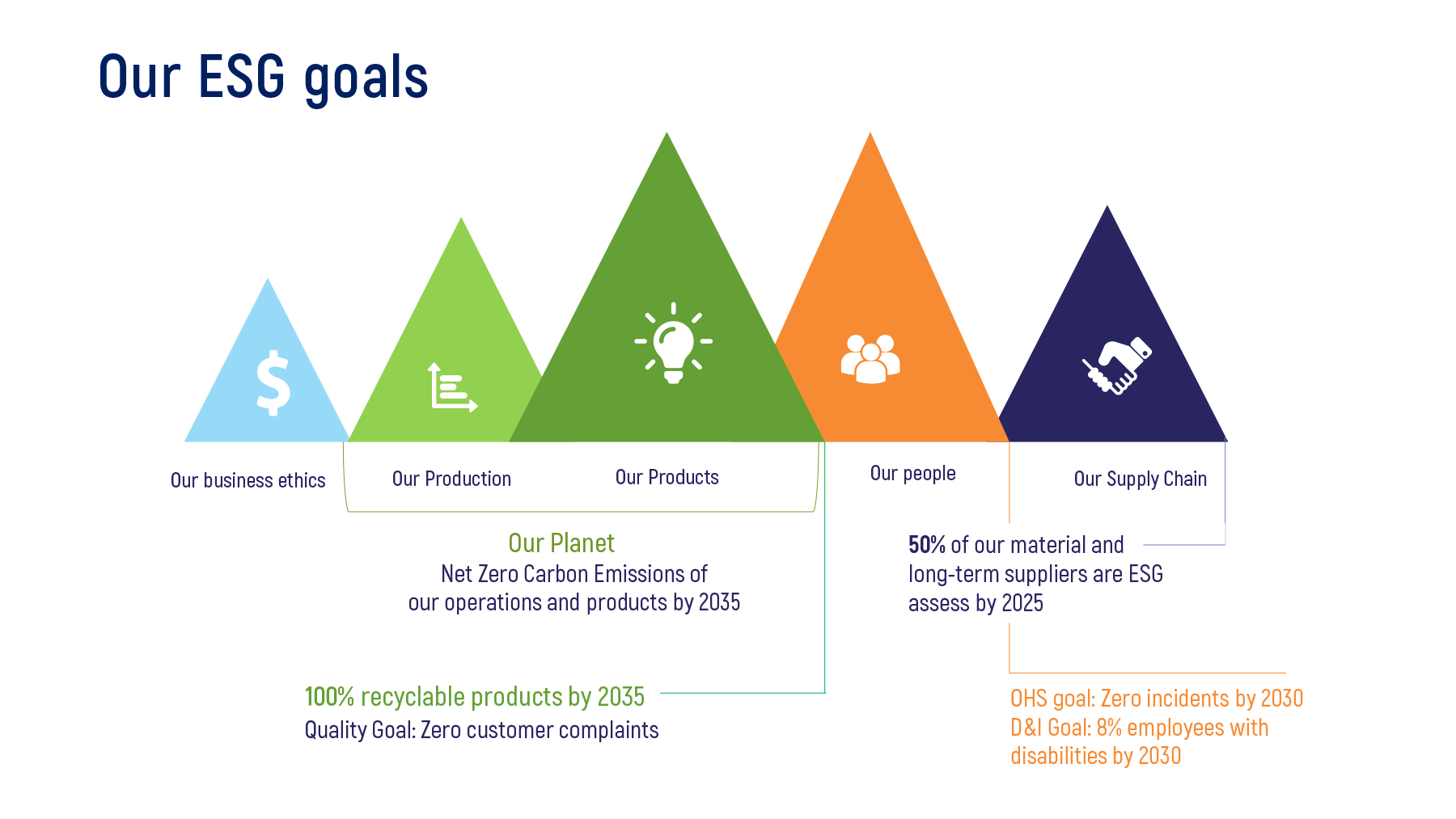

This is why our sustainability strategy addresses our products and manufacturing practices in the lead – in which we have a significant environmental impact. Immediately afterward the strategy focuses on our people and our community. Finally, we have placed our business conduct, which is the basis of everything we do, but we are confident in the foundations we have laid and we ensure our ethical business conduct, based on integrity and promoting trust with all our stakeholders.

The company has defined supporting KPI’s to achieve the goals as part of a metrics team and an organizational excellence team.

Promoting the UN SDGs

The 17 Sustainable Development Goals (SDGs), are an urgent call for action by all countries and organizations in a global partnership. The Goals aim to end poverty and other deprivations together with strategies that improve health and education, reduce inequality, and spur economic growth – all while tackling climate change and working to preserve our oceans and forests.

We have performed an analysis of the SDGs that are most relevant to our activities and in which we have significant impact potential. Here are the selected SDG’s we set ourselves to promote as part of our ongoing activities:

As a company engaged in the production of plastic packaging, we see great responsibility in implementing innovation, thinking and working together with all our stakeholders, to promote solutions to reduce the environmental impacts of this raw material on the planet. In addition, as an organization engaged in the field for about 50 years, we have experience, knowledge and collaborations that can help formulate solutions that enable the use of packaging that address consumer needs, safety of stored materials and prevention of external environmental damage – along with reducing the environmental impact of packaging itself.

We strive to examine and implement solutions that can help ensure a fully circular economy, taking into account all existing restrictions and limitations. We set ourselves to meet the goal of 100% recyclable products by 2035.

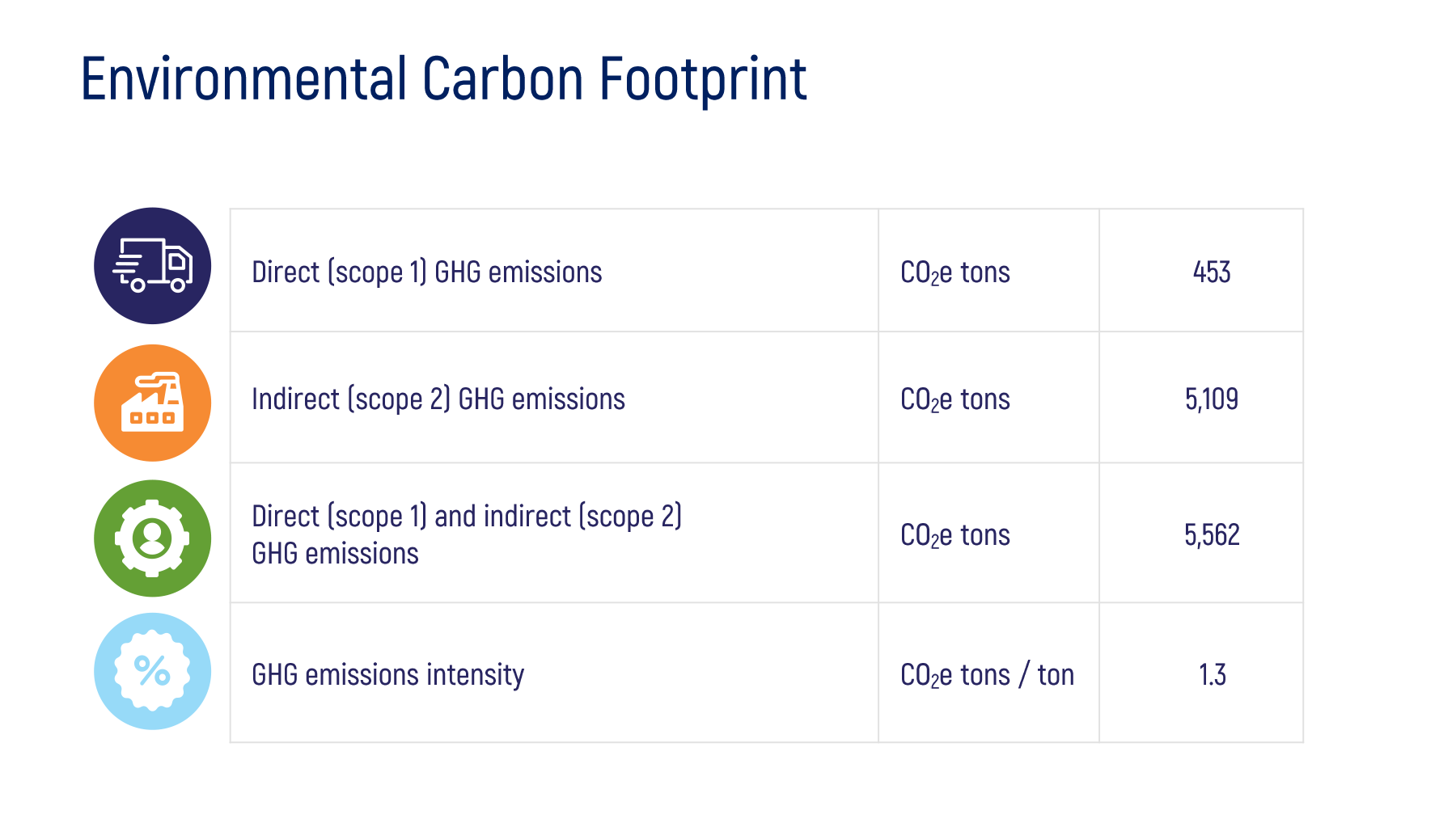

Our GHG emissions in 2021:

As a manufacturing company, we work to reduce our environmental impacts throughout our value chain – in our factories, with our customers, our suppliers and, as mentioned – in our products. We are constantly working to comply with all environmental regulations and laws and implement strict beyond compliance approach. Therefore, we have set ourselves a target of Net Zero Carbon Emissions in all our operations and products by 2035. To this end, we work on improving our environmental impact in our operations, products, with our customers, suppliers and employees.

The climate crisis increases the likelihood of recurrence of environmental extreme events. We, at LOG examine the implication of the impact of these risks on our operations and we search for ways to prepare accordingly. At the same time, we are examining opportunities in the field.

As a company that promotes innovation, we invite start-ups and our stakeholders – mainly our customers and suppliers – to examine and formulate collaborations for the implementation of new technologies and materials that promote a circular economy

We are committed to reducing our energy consumption in all our operations, through the adoption of environmentally friendly technologies and investment in energy-efficient equipment.

We maintain sustainability programs that help us reduce environmental impacts from our initiatives such as reducing waste and supporting recycling. Employees are required to adhere to Company-wide programs, and to be familiar and comply with environmental laws and regulations that relate to our specific work responsibilities. This includes complying with regulations related to the reporting, approval and registration of chemical ingredients used in our production and products.

LOG’s Environmental Sustainability Policy – Click here

Plastic

Plastic is a polluting material, but it also has many benefits – from the consumption of energy needed to process it, to the continued emission of greenhouse gasses generated in the process to the weight and transportation costs of the final packaging. Therefore, it is necessary to find ways to maximize its recycling capabilities to eliminate its harmful environmental impact and still enjoy the benefits it provides to cosmetics, food and pharmaceuticals goods.

It is important to emphasize that most of our production is intended for pharma companies and accordingly, we are subject to limitations that narrow the scope of the solutions available to us.

Reducing the environmental impact of our products

We operate in a particularly challenging environment that depends on the existing recycling infrastructure, regulation and relevant needs for maintaining the quality and safety of the contents of our storage packaging products, the cooperation of customers and consumers and most importantly – innovation in developing new raw materials that address these challenges.

LOG has adopted the definition of recyclable materials according to international standards (ISO 14021, ISO 18604):

“Characteristic of product, packaging, or associated component that can be diverted from waste stream through available processes and programs and can be collected, processed, and returned to use in the form of raw materials or products”

To this end, recycling must be ensured as defined:

- Existence of a system for collecting and separating the material for recycling purposes

- Existence of a recycling process that will prepare the material for the production of a new product

- Existence of a market that will absorb the recycled material for the purpose of manufacturing products

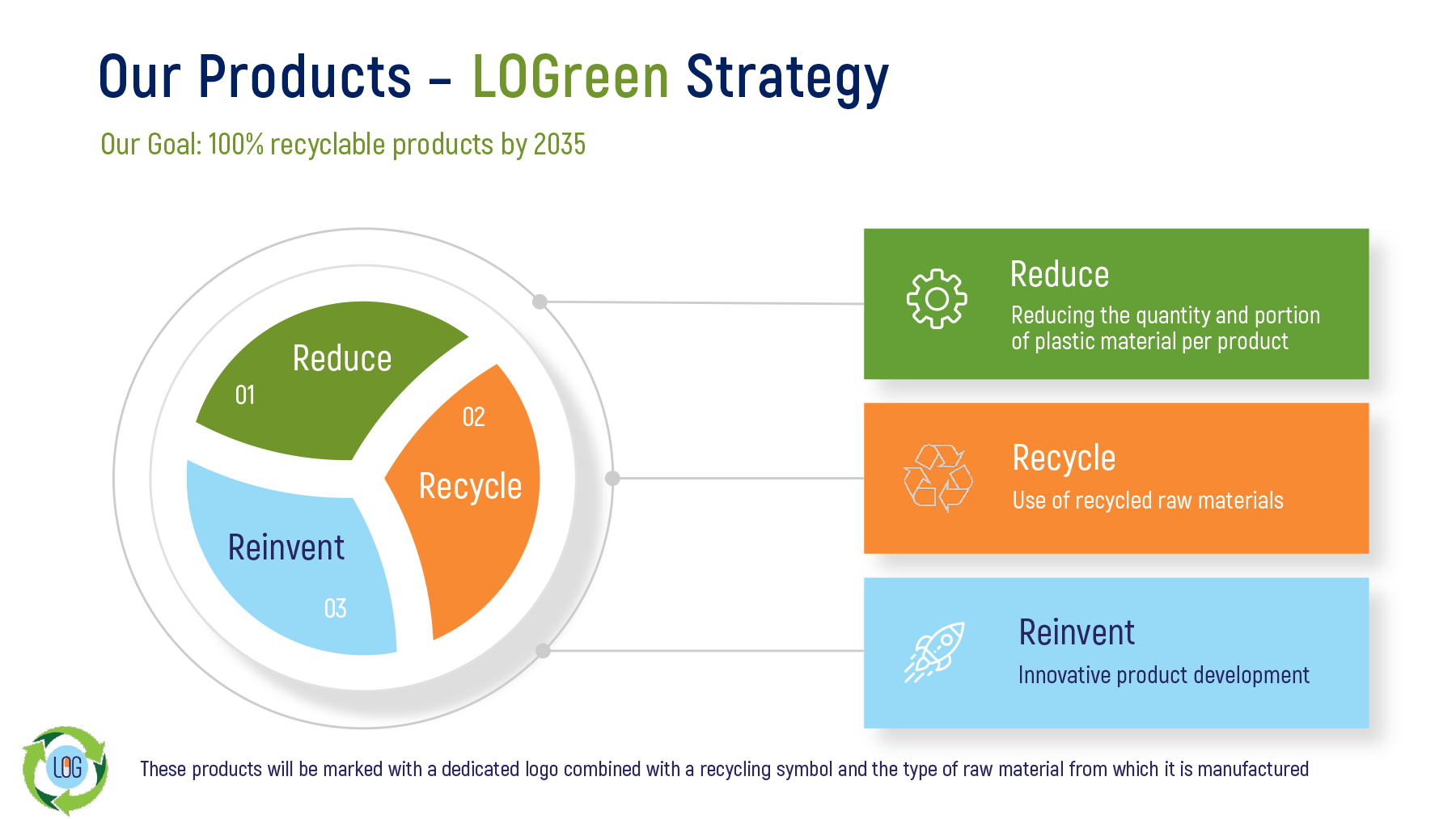

We have formulated a strategy for developing an improved product line that addresses these challenges – the LOGreen strategy which based on three selected Rs – Reduction, Recycling and Reinventing:

As a company that promotes innovation, we invite start-ups in the field to contact us in order to examine the possibility of cooperation and examine the new technologies in our factory as a beta-site for innovation. We seek to help new technologies enable the industry to promote breaking-through solutions through the PlasticTech accelerator.

We are committed to working towards forming collaborations with leading entities that promote a circular economy and possess knowledge, tools and experience in the field such as the Alan MacArthur Foundation, academic bodies, BASF and others.

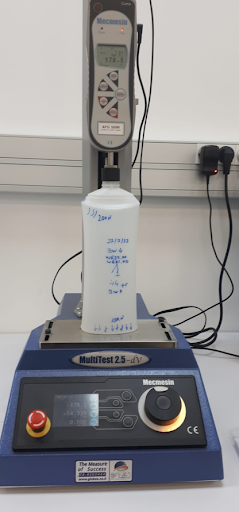

We are committed to continuous learning and improvement for more sustainable and recyclable products using international standards (such as ISO 16001), leading manuals such as the RECYCLASS manual maintained by the European Plastic Recyclers Association and conducting frequent recycling compatibility tests.

Reducing the environmental impact of our production sites

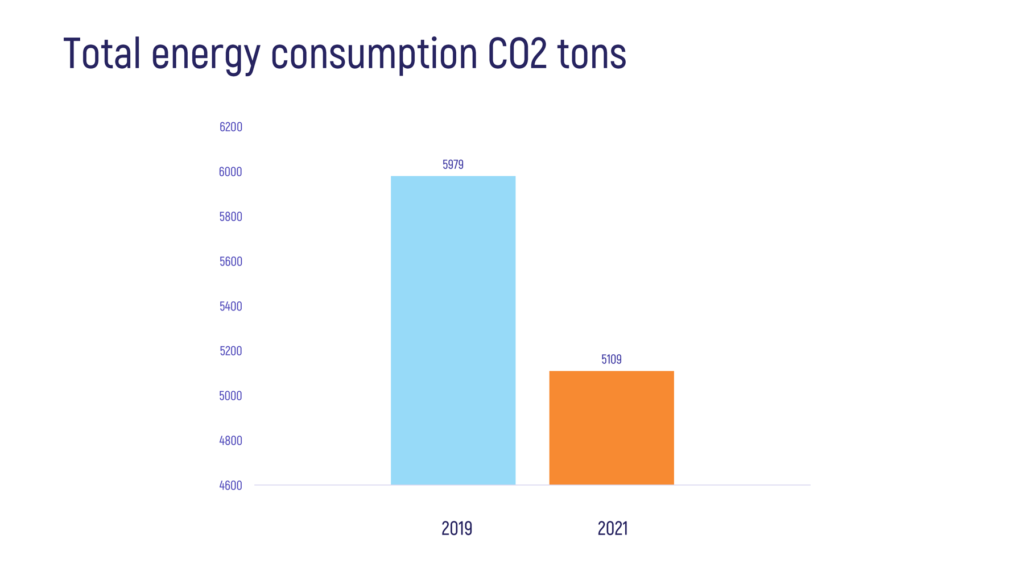

We are committed to reducing our energy consumption in all our activities, through the adoption of environmentally friendly conduct and investment in energy-efficient equipment. In recent years, we have promoted the use of renewable energy by installing a solar field at our production site in Israel and we will continue to work to integrate renewable energy solutions in all our sites.

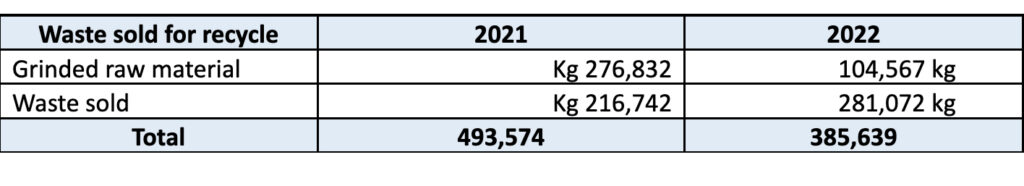

We treat all the waste that comes out of our factories and direct significant portions to recycling plants and suppliers that help us ensure a circular economy implementation. We operate according to the “reduction, recycling, reuse” approach in all our facilities, and are constantly looking for practical and innovative ways to avoid transforming our waste to landfill.

We do not work with hazardous materials and that is why we do not pollute – not by air or by wastewater.

As part of our activities, we strive to minimize water use and recycle water as much as possible. We have reduced the use of water to the required minimum and will continue to search for ways to improve water use in our facilities.

We will work to improve our internal processes so that we can return self-shredded material back to production in order to promote recovery of raw materials, based on quality approval per process.

The climate crisis increases the likelihood of recurrence of environmental extreme events. We, at LOG, examine the implication of the impact of these risks on our operations and we search for ways to prepare accordingly. At the same time, we are examining opportunities in the field.

Energy efficiency ventures

In the last three years, we have been able to slightly reduce energy consumption despite the increase in production during 2020. In Israel, we enjoy green energy due to solar panels installed on the factory roof. In addition, we promote energy efficiency initiatives and thus reduce the use of electricity.

In recent years, we have initiated a number of energy efficiency ventures in favor of improving work processes, saving inputs, and preserving the environment. Here are some key examples:

Ventures in Israel 2020-2021:

- Conducting an energy survey and sharing results with the Ministry of Energy.

- Replacement of 200-ton and 125-ton refrigeration chillers that have replaced old chillers over 10 years old.

- Replacement of two 40-year-old machines with an electric machine for injection and extrusion blow molding.

- Replacing the head forming a sleeve (4 -2) which allows doubling the work pace.

- Replacing molds that allowed for a 20% reduction in cycle time.

- Treatment of compressed air leaks.

- Disconnection of pasty facilities that have resulted in significant savings in energy consumption without compromising cycle times

Ventures in Hungary 2020-2021:

- Replacement of 24 socket cavities – tripled the production capacity at the same power consumption

- Assembly line replacement – quadruple the production of products with the same power consumption

We are proud that we have not received fines or lawsuits in the context of our environmental conduct.

Case Studies

Climate change – risk management

The climate crisis increases the likelihood of recurrence of environmental extreme events. We, at LOG, promote climate risk management to make our value chain resilient to all extreme scenarios that are expected. We recommend our suppliers to manage their environmental and climate risks as well in order to prepare for extreme scenarios.

Enhancing our employee’s environmental efforts

In order to ensure that our approach of promoting environmental sustainability succeeds, we are required to ensure the full cooperation of our employees – who are the source of our success. To this end, we work to promote environmental awareness among employees, communicate the importance we see in our work in the field and ensure that everyone recognizes our efforts

We work to apply the principles of reducing our environmental impact in factories, at headquarters but also provide employees with knowledge and tools for self-implementation, among family and friends.

Supporting our customer’s efforts to reduce product’s environmental impact

We are committed to working with our customers to develop integrated solutions tailored to the needs of all involved as well as the needs of the planet. To this end, we will promote proactive initiatives for joint thinking with our customers about ways to improve products that implement our shared environmental sustainability approach.

We offer cooperation and support to our customers’ moves to reduce their environmental impact by sharing the knowledge and experience we have accumulated in the field and therefore, offer guidance on prints on packaging, use of advertising sleeves, colors and more – so as not to impair the recycling capabilities of packaging products. We also encourage our customers to add the recycling symbols on the packaging in order to encourage and guide consumers how to recycle optimally.

Empowering our suppliers to improve their environmental practices

We are committed to advancing the concept of environmental sustainability among our suppliers, expecting them to demonstrate a responsible attitude towards the environment and inviting them to join forces and in order to a more significant environmental impact together.

Our employees and our community are the source of our strength, knowledge and success. Accordingly, we cultivate our relationship with them and see in this connection the source of everything we are.

Our core values are based on our people: Teamwork and Cooperation and Diversity and Inclusion.

Our Employees

We are committed to our employees – we respect, empower, reward and encourage our employees to be full partners in our endeavors. We encourage them to innovate, work collaboratively, be fair, demonstrate personal responsibility and respect their colleagues to maintain a work-life balance.

We maintain an ongoing dialogue with our employees in order to support mutual expectations to the satisfaction of all. We expect our employees to be professional and in control of all activities within their area of responsibility. In addition, we expect them to demonstrate personal responsibility when it comes to avoiding risks and disclosing sensitive information about the company, including on social media.

Maintaining the privacy and dignity of employees is extremely important to us. As part of our privacy protection efforts, we make sure to keep the information we collect and process in relation to our employees private and confidential. Use of this information is done in strict compliance with the provisions of the Privacy Protection Laws and use of the information for the purposes for which this information was collected only.

We adhere to ethics in interpersonal relationships in society and encourage the obligation to report interpersonal relationships in cases of power relations. In these cases, we are working to change roles or disconnect conversions.

We avoid conflicts of interest and exploitation of business opportunities for personal needs in the course of our work, we act solely for the benefit of the company, and we do not let foreign considerations interfere with our judgment. We do not accept gifts and we do not use inside information to make personal profit.

We make sure not to employ workers under the age of 18 and to ensure fair working conditions, their health and safety and their wellbeing. All our employees are hired on a permanent contract.

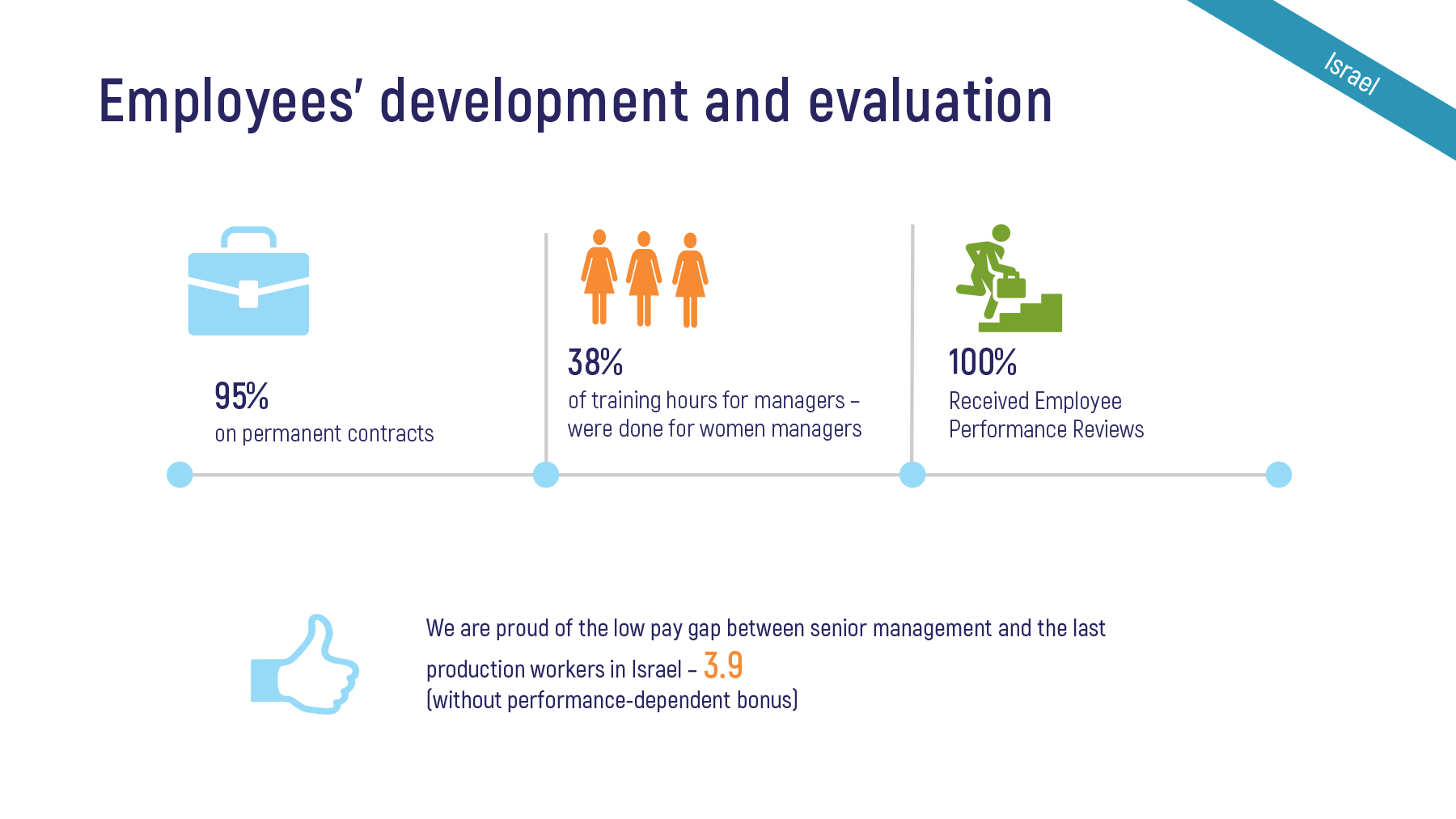

100% of our employees receive formal performance reviews during yearly reviews

Our meetings with employees are evidence to our efforts. From the analysis of the meetings with the employees that take place during the year, we learn about very high employee satisfaction from the employment relationship and welfare conditions. As part of the meetings, the employees make suggestions for improvement and we work immediately to examine their implementation. At the same time, we are also asking regarding conservation issues to get full feedback on our initiatives.

In addition – this year, for the first time, we awarded bonuses to all production workers in accordance with the evaluation of their performance in the factory.

Employee empowerment

Employees are the source of our strength and therefore we invest resources in training and development programs. In 2021, three of our employees in Israel participated in unique programs for higher education subsidized by the company. Another manager in Hungary participated in a unique and tailored development program that led to his promotion from warehouse manager to production and warehouse manager.

100% of our employees receive a performance review. Bonus is paid according to the assessment results.

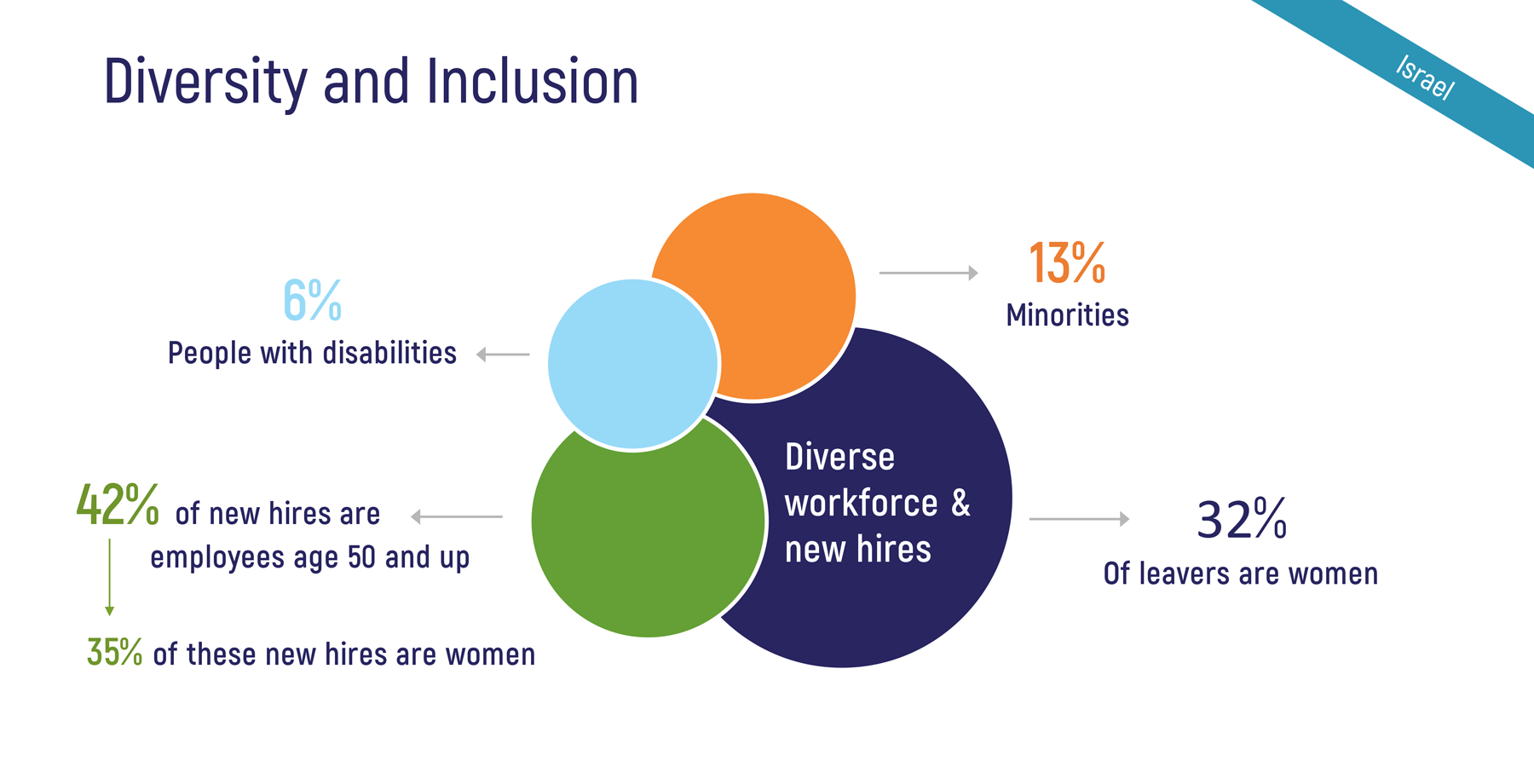

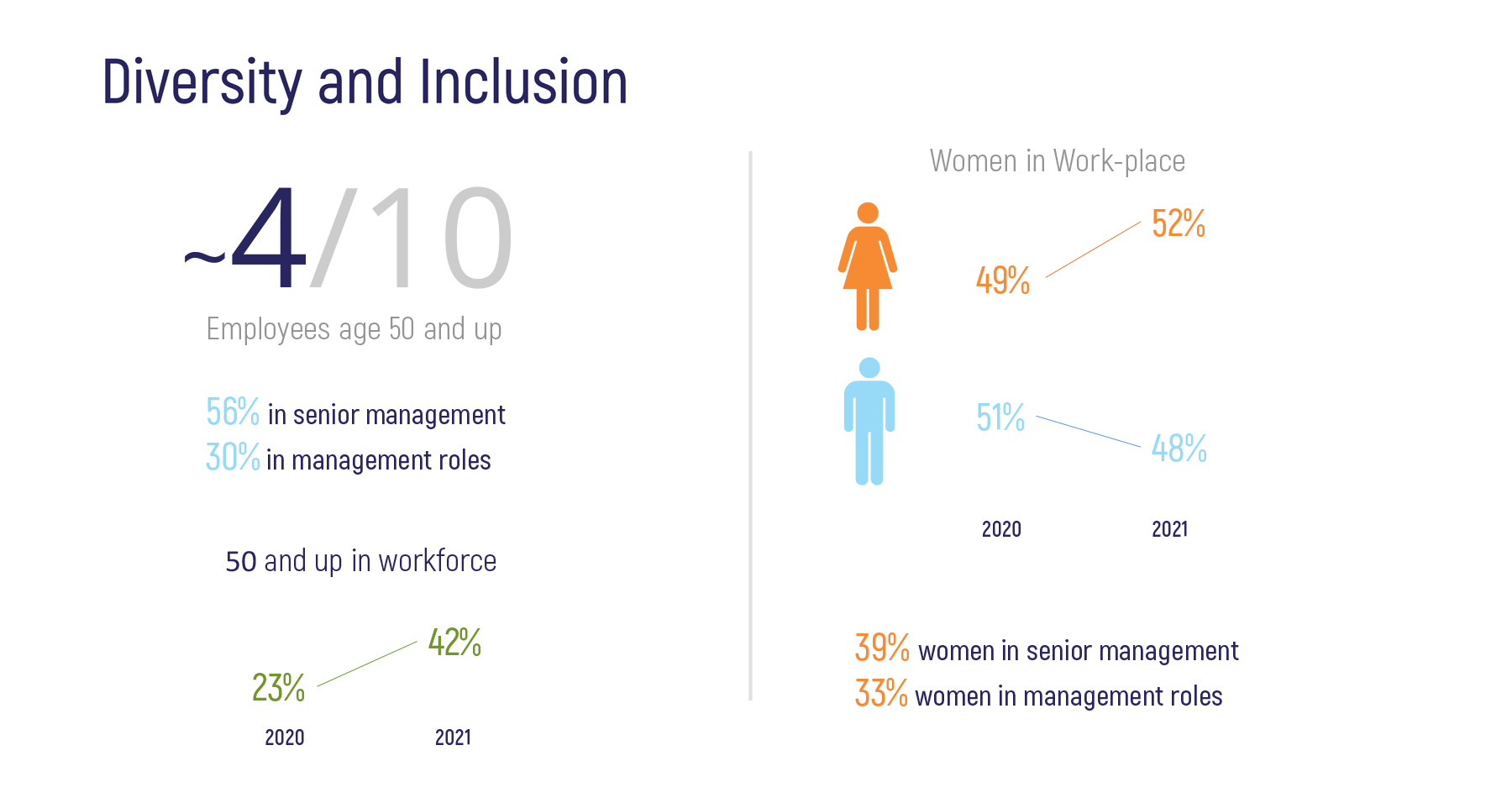

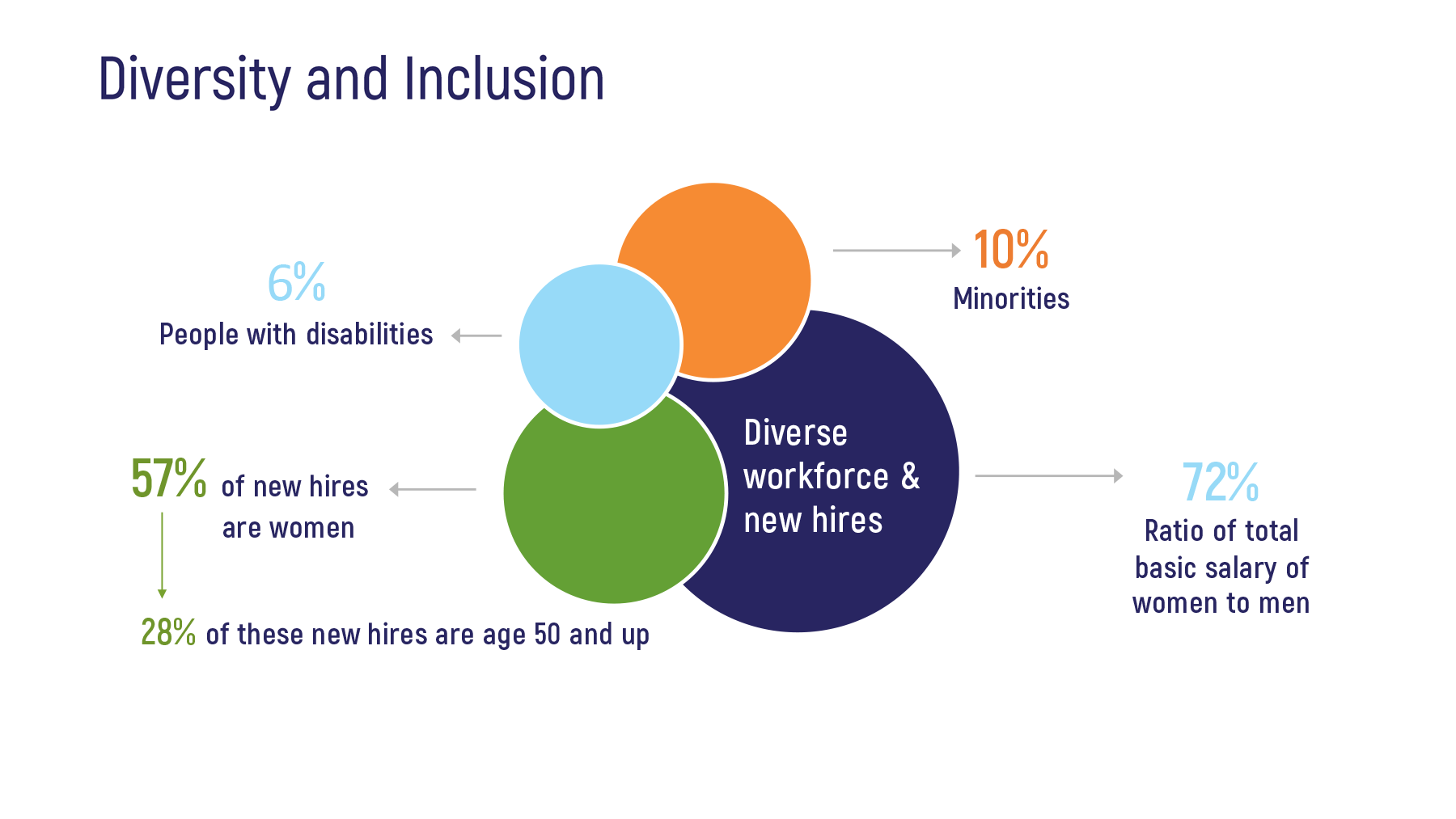

Diversity and Inclusion

We respect and believe in the value of each individual. Our business was built on honesty, openness and acceptance of others’ views, culture, experience and knowledge – that is the only way we can thrive and develop our full potential.

We give everyone an equal opportunity, encourage employment diversity and invest resources in personal development. We believe that diversity will allow the uniqueness of each of us to enrich and strengthen the work environment while adapting to the changes that apply in the business environment and the future labor market.

We oppose any discrimination based on race, skin color, religion, physical disability, national origin, age, sexual orientation, gender, gender identity and gender expression, marital status, marital status or any other characteristic of diversity. We will not tolerate any form of harassment, violence or threats among us.

We are committed to respecting and promoting human rights. We will never be part of Modern Slavery, Human Trafficking and Child Labor or any way of exploiting human beings.

We give everyone an equal opportunity, encourage employment diversity and invest resources in personal development.

LOG’s Human Rights, Diversity and Inclusion Policy – Click here

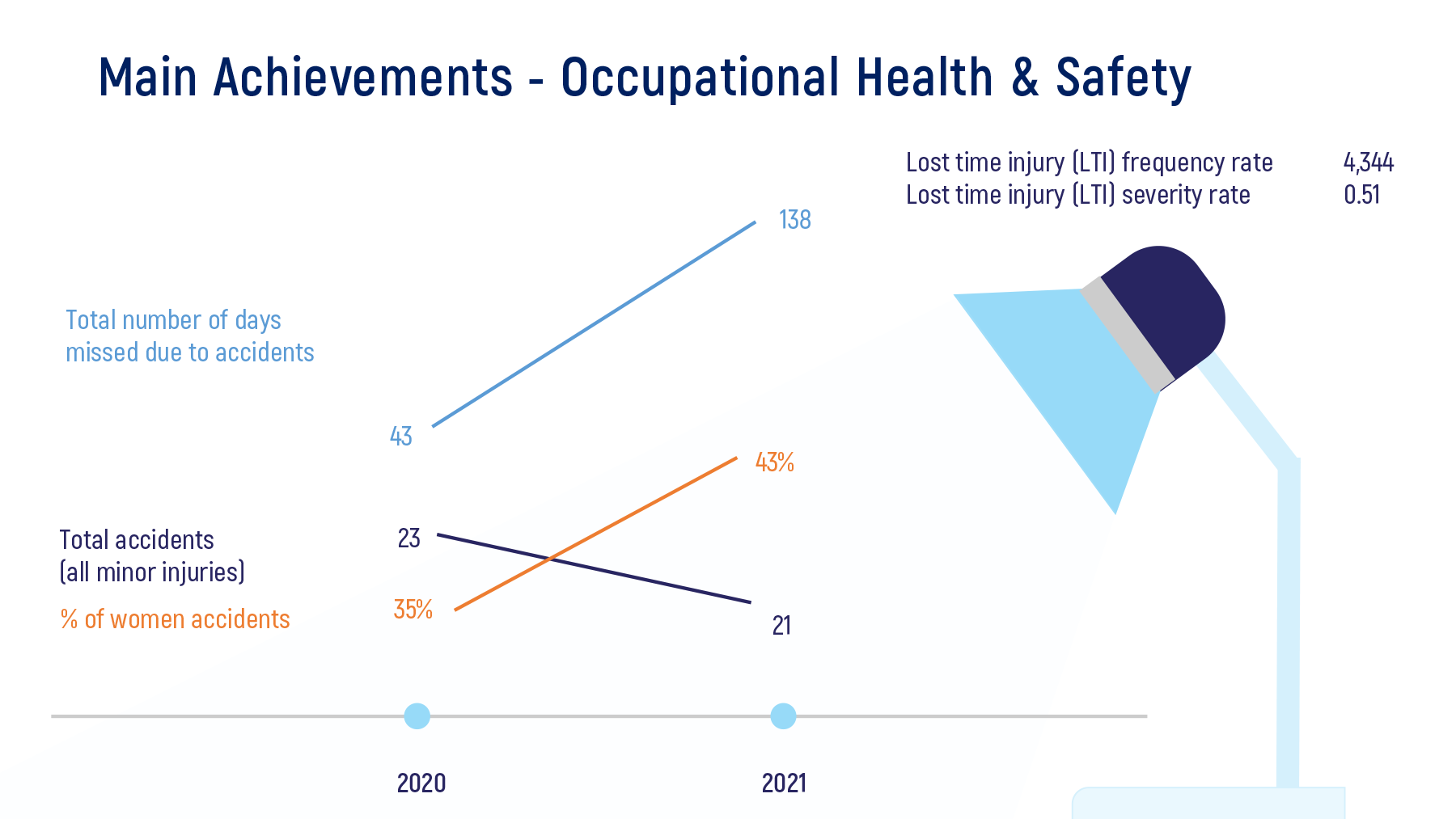

Occupational Health and Safety

LOG considers it of paramount importance to ensure the health and safety of its employees and aims to provide the infrastructure required for the success of its efforts in the field. To this end, we have designed a proactive approach to Occupational Health and Safety (OHS) based on mechanisms of monitoring, control, management and continuous improvement. We invited our employees to formulate with us the ways to improve our conduct in the field and set appropriate mechanisms, action plan, procedures, safety trustees and resources to meet the ambitious goal we set for ourselves of zero accidents by 2025.

LOG encourages its employees to live a healthy lifestyle through a variety of options for participating in sports activities and training.

The company provides its employees with a variety of financial supporting mechanisms, including wage advances and benefits in addition to bonuses and subsidies for lunches at a rate of about 85%.

In addition, LOG provides its employees with collective health insurance that provides optimal protection with extended coverage.

Promoting employee safety and well-being among our customers and suppliers

We are committed to promoting awareness of the importance of maintaining employee health and safety among our customers and suppliers. To this end, we share with them our efforts in the field and invite them to take proactive approach on the matter.

LOG’s Occupational Health and Safety Policy – Click here

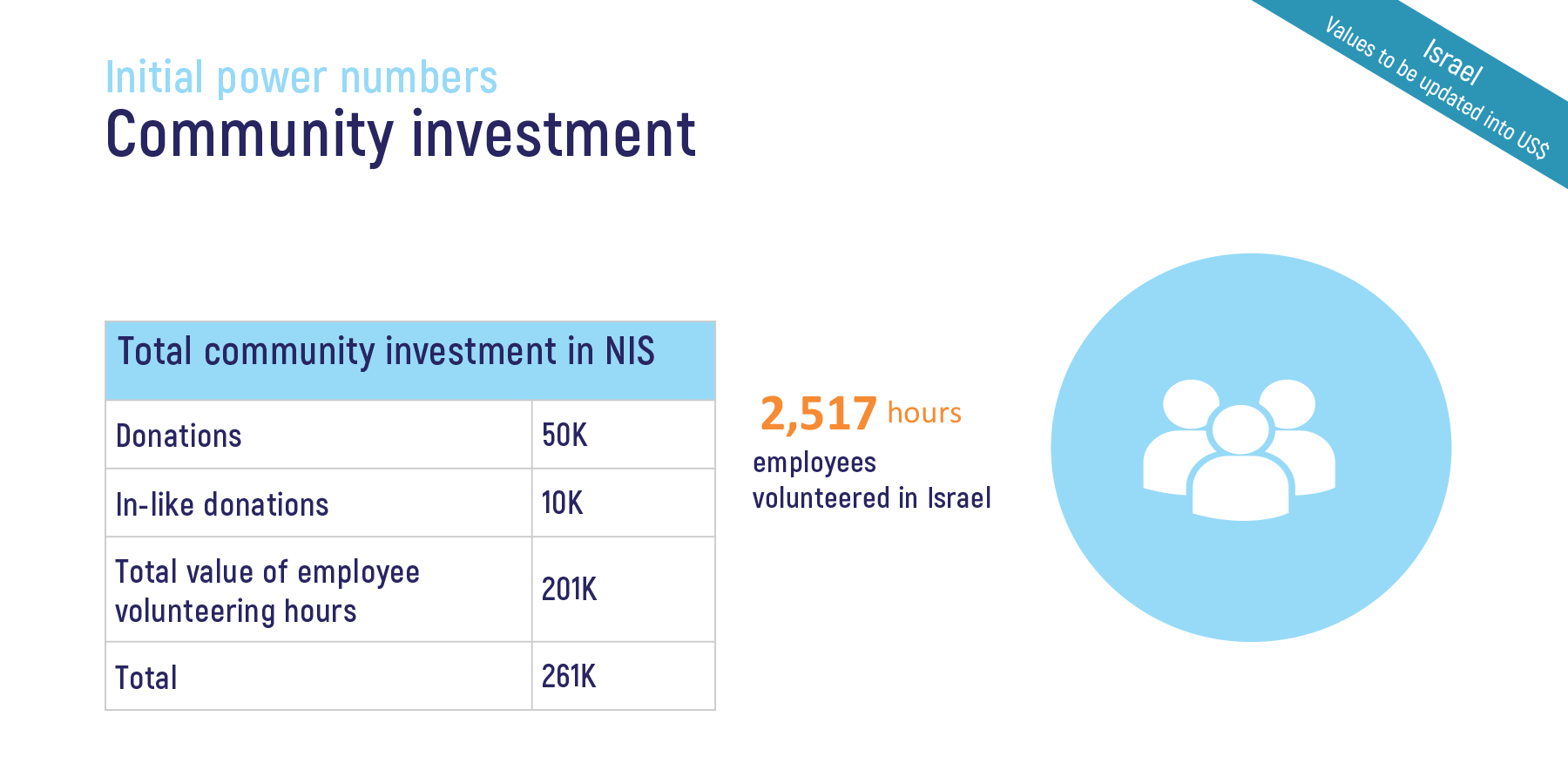

Our community

Kibbutz Ashdot Ya’akov Ihud established our factory with the aim of addressing the older members of the kibbutz who needed comfortable and suitable employment. In accordance with these values and foundations, we will continue to be committed to supporting the social and environmental needs of the communities wherever we operate. The resilience of the community in which we operate will affect our business, workforce and sustainability.

We are attentive and caring to the various communities, conduct an open and ongoing dialogue and promote local initiatives to support their well-being while focusing on promoting diversity and inclusion. We encourage our employees to be personally involved in the social activities we initiate.

Our Community investment strategy

LOG Plastic Products Ltd. sees itself as an integral part of the communities in which it operates, in Israel and abroad. LOG strives to be involved in these communities and contribute to their prosperity through community involvement and social activities for different populations and sectors, in areas and activities that are related to the social goals that LOG sets for itself.

LOG believes that community investment and social involvement will help create a stronger, healthier and more prosperous community and society. For that end, LOG encourages engagement with the community in which we live and the involvement of employees in volunteering activities. This perception stems from the understanding that this activity enables the empowerment of the employees alongside the contribution and cultivation of the community in which we operate.

Case Studies

Our business ethics

We are committed to conducting ethical business towards all of our stakeholders. Our core values are Fairness and Accountability and Excellence – innovation and high quality and we uphold our commitment through our daily practices.

We have formulated this commitment into our Code of Ethics and in a series of policy documents that serve as a compass, for us and our partners, for a fair and ethical business conduct – because we know of no other way to do business.

We invite you to read our policies on:

All our employees are required to undergo training on the Code of Ethics as well as, policies to prevent bribery and corruption.

Compliance with the law is a necessary and minimal condition for ethical conduct. We consider ourselves committed to meeting higher standards than those set by the laws and regulations applicable to our operations, wherever we operate.

We respect competition and competitors and we are committed to maintaining fair and proper competition rules in our relationships with and aside of our competitors. We are committed to full compliance with the relevant global laws, with particular care to ensure compliance with antitrust laws.

We are proud that in recent years we had no incidents of non-compliance with regulations and/or voluntary codes concerning corruption, anti-competitive behavior, anti-trust, product health and safety and data privacy and security.

Excellence – innovation and high quality

Our excellence consists of excellent people, processes and innovation and strict adherence to quality!

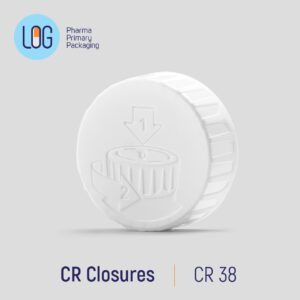

Established in 1971, LOG Pharma Packaging is a pioneer in packaging innovations and the trusted partner of global pharma companies, providing the industry with unique and innovative packaging solutions for oxygen and moisture sensitive drugs. LOG has combined 50 years of industry experience with the innovative Israeli state-of-mind to deliver the future of pharmaceutical packaging while being fully compliant with US FDA and European pharmacopoeia standards.

LOG earned its business partner’s confidence and trust as a company that deliver advanced innovation that meet current and future market needs. As a well-known market leader in innovative solutions for sensitive drugs, LOG will continue to offer active and passive advanced products; Packaging with child and adult protection (Child resistant and Senior friendly); Counterfeit solutions; Smart packaging and more.

LOG is also committed to improve its impact on the planet. Log will invest its efforts on developing new innovative and sustainable products that will offer solutions to the environmental challenges plastic packaging holds.

LOG strives for the highest quality in primary pharmaceutical packaging. We value the trust placed in us by our customers and work constantly to anticipate and exceed requirements. Our quality standards apply across the entire organization and we continually review all our processes for continual improvement. We are fully committed to compliance with GMP standards, and the entire LOG team focused on our goal of Zero Customer Complaints.

At LOG, we seek every opportunity for improvement, by constantly inspecting, surveying and auditing all processes across all departments. We embrace the challenges as an opportunity for excellence.

To achieve consistent improvement in our performance, all levels of our professional and highly skilled workforce are fully engaged in the LOG quality culture. At LOG, quality forms an integral part of every job definition. We encourage taking personal responsibility and full participation among all employees.

LOG’s Quality Policy – Click here

We conduct a full customer survey once every 2 years to keep an open communication channel with our customers, to learn more of their needs and expectations from us and to find ways for improvement. We also analyze on going inquiries. Our last survey conducted in 2020 showed an average satisfaction rate. We have analyzed all customer inquiries during 2020.

Following the latest customer survey and the understanding that customers are looking for quality while meeting delivery times tailored to their needs along with a competitive price, we have made extensive investment in new machines in Israel and Hungary. These machines will deduct depreciations, which will lead to an improvement in quality and delivery times to our customers.

Information security and privacy

We see great importance in maintaining the information we hold with special emphasis on information about our employees, our customers and other third parties with whom we do business.

In 2019, we began formulating clear procedures in the field, conducting information security training for employees and conducting risk surveys and audits using an external consulting company that specializes in the field. We initiated these practices in Israel and we plan to start implementing them in Hungary during 2022.

We have invested heavily in protecting the data and information we received and we will continue to do so in order to ensure the confidentiality of our data.

25% women in Israel BOD – one of whom is the chairperson; 50% women in Israel management board

25% women in Hungary BOD ; 33% women in Hungary management board

Our Corporate Governance

The Board of Directors of LOG Israel is compose of 10 members. One of the BOD members completed his role but still has no replacement. Two members of the board are women – one of whom is the chairwoman of the board.

LOG Hungary (LHU) Board of Directors is composed of four members, including one woman.

The following is the details of the members of the group’s board of directors, which presents the diverse professional experience:

Dr. Nurit Nahum – Chairperson

Dr. Nurit Nahum is experienced in a wide range of business capacities, including serving as the CEO of an international private equity investment company, the VP of Business Development of a leading industrial, publicly- traded company in Tel Aviv stock exchange, and the manager of an Israel-based PWC consultancy group.

Mrs. Nahum serves on boards of global listed companies as well as privately held, and she is highly experienced in leading strategic turn arounds, global business development processes, M&As and global joint ventures.

Nurit Nahum holds a Ph.D. in Strategy and Entrepreneurship from Tel Aviv University, she has graduated Harvard Business School Executive Education Program and an affiliated researcher at Jönköping International Business School, Sweden.

Chen Eitan

Mr. Chen Eitan is a member of Kibbutz Ashdot Yaakov Ihud. 56 years old.

Chen holds 25 years of managerial experience in a variety of senior management positions.

For 10 years Mr. Eitan served as business manager (Farm Manager) at Kibbutz Ashdot Yaakov. For 5 years he managed the poultry breeding division at ‘Of Tov’, was a national sales manager at ‘Fibro Israel’, an international company for the production and sale of vaccines, medicines and animal feed supplements. Currently, Chen is the business manager and marketing manager at Kibbutz Mishmar HaEmek at ‘Mishmar HaEmek Chicks’ company.

Mr. Eitan currently serves as a director on the Board of Directors of ‘Tzemach Mifalim’ and ‘Tzemach Leasing’.

Inbar Alter

Mr. Inbar Alter hold a degree in computer science and mathematics from Bar-Ilan University.

For the last 10 years, Mr. Alter is the CEO of ‘zemach leasing’, a leasing company owned by 31 kibbutzim.

Mr. Alter have Board experience and he is currently a Board member at “deshen hatsfon” a fertilizer company, and “mishkei emek hayarden” which is a finance organization.

Arie Weisberg

Mr. Arie Weisberg serves as a member of the Board of Directors of Lumenis Ltd., an Israeli Nasdaq-listed company, Plastopil Hazorea Company Ltd., an Israeli TASE-listed company, Advanced Vision Technology Ltd., an Israeli company listed on the Frankfurt Stock Exchange, and Metzerplas Cooperative Agricultural Organization Ltd.

He also acts as a consultant to various companies.

Mr. Weisberg was President and Chief Operating Officer of the Company, after serving in various roles: Co-President for Global Resources, Executive Vice President for Global Resources, Chief Financial Officer, Corporate Vice President for Finance and Administration, co-general manager of Orbotech S.A. and director of finance and operations of Orbot’s subsidiary in Belgium.

Prior to joining Orbot he was general manager of Sinus Ltd., a manufacturer of internal combustion valves, and served as west region general manager of Solcoor Inc.

Mr. Weisberg received his bachelor’s degree in agricultural economics from the Hebrew University in Jerusalem.

Ronen Zexer

Mr. Ronen Zexer holds a bachelor’s degree in economics and management and MBA from Tel Aviv University.

From 1988 to 1995 Mr. Zexer served as CEO of Log Plastic Products. From 1995-2004 held senior managerial positions in a hi-tech multi-national NASDAQ traded company. From 2004 -2011 held CEO positions at two hi-tech Start-Up companies and 1 mid-size agro-tech company in Israel. From 2011 – to present independent consultant.

Yaniv Barkan

Mr. Yaniv Barkan in a board member of Log Since 2014, serving simultaneously as a member of the Kibbutz’s Financial management. Since 2019, Yaniv is the Chairman of the Kibbutz’s financial and community managements.

Mr. Barkan is also a Single-Family office of a high net worth individual, specialized in portfolio-management and Real Estate activity, as well as managing the family’s Philanthropy funds.

Mr. Barkan holds a B.A Summa cum laude in Psychology and an MBA – Management major from Bar-Ilan University.

Mr. Barkan is a Member of Kibbutz Ashdot Yaakov Ihud, and a proud father of 4 princess.

Yishai Shapira

Mr. Yishai Shapira serves as a member of LOG’s Board of Directors since .2019

He serves as a director on behalf of the owner by virtue of his position as the business manager of Kibbutz Ashdot Yaakov Ichud.

In the past decade, Mr. Shapira has held a series of kibbutz management position, as chairman and business manager. In addition, Mr. Shapira serves as chairman of the Health Food Companies association (including the brands Harduf, Hassade, Vega, Ecover, etc.).

In the 1990s, Mr. Shapira was one of the founders of the “Harduf” organic food company (Tnuva Group), and served as the company’s CEO from 1996-2012.

Mr. Shapira studied agricultural economics at the Hebrew University.

Aliza Barkai

Ms. Barkai serves as the director of the LOG Plastic Products, Kibbutz Sde Eliyahu holdings, the Jordan Valley farms secretariat, the board of directors of Kinneret College and in the economic management of Ashdot Yaakov Ihud.

Ms. Barkai served as business and finance manager of different kibbutzim for the last twenty-five years.

Graduate of Geography Studies at Tel Aviv University and Business Administration Studies at Bar Ilan’s Branch at Kinneret College.

LOG Hungary (LHU) management team is composed of six managers, two of whom are women.

Board committees:

- The Finance Committee, which also serves as the Audit Committee, is chaired by the Chairman of the Board

- Risk Management Committee

- In addition, there are a variety of other committees: a community donation committee; Costing committee; Raw Materials Committee; Inventory Committee; Construction Committee; Quality Committee; Depreciation Committee

Starting in 2020, the Board of Directors will hold an annual meeting of one of its committees on sustainability.

The risk management committee holds an annual meeting after a preparatory discussion in the group’s management. The discussion based on a dedicated survey conducted by Quality Assurance as well as a risk management report conducted by a product development unit. Insights from these reports presented for in-depth discussion in favor of making decisions for further action.

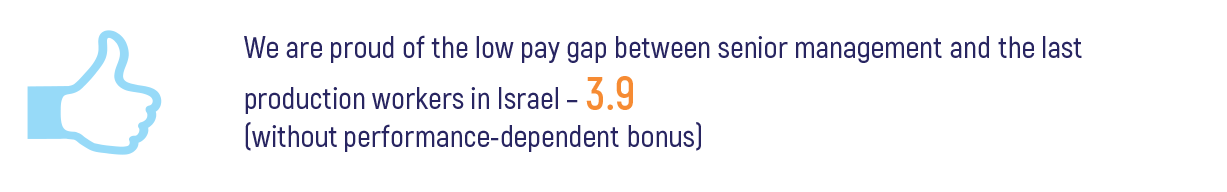

LOG Board of Directors approved the salary and remuneration policy on September 2020. According to the policy, salary discussions will be held once every two years with the participation of the CEO, VP HR and relevant VP.

LOG is committed to conducting business in a responsible, fair and an ethical manner and with full compliance will the international and local laws. To uphold this commitment we expects all our stakeholders to promote the same business conduct and we strive to conduct business only with suppliers that share the same commitments and that promote the highest ethical standards.

We see our suppliers as our key business partners for our joint success. To this end, we believe that full cooperation for the promotion of ESG – including concern for human rights, employees’ health and safety, community support, sustainable raw materials, transport efficiency and activities to reduce environmental impact – will lead to a resilient business relations, better economic, social and environmental conduct and a better world for future generations.

We strive that our suppliers will embrace the ESG pathway and for that end, we will promote this approach in all our interactions and will offer guidance using this policy that will serve as our ‘Suppliers Code of Conduct’ alongside our LOG Code of Ethics. In addition, we set a goal to assure that 50% of our material and long-term suppliers are ESG assessed, by 2030.

In 2021, we updated our ‘form of establishment of a new supplier’ and combined questions in different ESG areas. In addition, we conducted a supplier evaluation questionnaire and began collecting information about supplier activity in the field. In 2022, we plan to expand these efforts and promote the collection of environmental data in favor of initiating Scope 3 calculation among our key and material suppliers.

We see an opportunity for mutual enrichment and development through meetings with our supplier and promoting multicultural, sectoral, inclusive and enriching joint work routines. That is why we encourage diverse procurement – working with suppliers that promote diverse employment and / or represent diverse under-employed groups such as: women-owned businesses, minorities, people with disabilities, etc.

LOG’s Responsible Supply Chain Policy – Click here

Fair and diverse procurement

We make sure to act responsibly, fairly and caringly towards our suppliers. We share with them the ethical values and principles of behavior we have set for ourselves as well as our expectations for promoting sustainability and responsibility for society and the environment. We therefore prefer working with suppliers that share the same values.

We see an opportunity for mutual enrichment and development through meetings with our supplier and promoting multicultural, sectoral, inclusive and enriching joint work routines. That is why we encourage diverse procurement – working with suppliers that promote diverse employment and / or represent diverse under-employed groups such as: women-owned businesses, minorities, people with disabilities, etc.

Promoting environmentally sustainable procurement

As an organization that was founded 50 years ago, we have experience, knowledge and collaborations that can formulate solutions for a more sustainable industry. Our suppliers are an important partner to help us fulfil our ambition for a circular economy and the goals we set to ourselves to reduce our environmental impact – focusing on our products and production sites.

To that end, we will learn what our suppliers’ commitments in the field are and will invite them to offer new and environmental raw materials and solutions.

Suppliers shall ensure that their facilities comply with environmental laws, including all applicable laws related to waste disposal, air emissions, discharges, toxic substances and hazardous waste disposal. We expect our suppliers to take commitment to further invest in reduction of their environmental impact and promote renewable energy use, minimize their water consumption and work on was to measure their progress.

Furthermore, suppliers shall diligently manage their supply chains to support responsible sourcing.

Joining forces to reduce our product’s environmental impact

We are committed to working with our suppliers to develop integrated solutions tailored to the needs of all involved as well as the needs of the planet. To this end, we will promote proactive moves for joint thinking-sessions with our suppliers to promote sustainable production and products.

Empowering our suppliers to improve their environmental practices

We are committed to advancing the concept of environmental sustainability among our suppliers, expecting them to demonstrate a responsible approach towards the environment and inviting them to promote their practices in the field together through combined efforts.

The first training sessions we held to our food suppliers in Israel was on the subject of employing people with disabilities. We plan to expand these empowerment sessions during 2022.

Material suppliers ESG assessment

During 2021, we conducted our first material supplier’s assessment in Israel. 41 responses were received. About 30% have ESG targets while 73% have environmental policies. Similar rates also been found regarding the existence of human rights policies, diversity and inclusion, employee health and safety, anti-bribery and corruption policies and more. These data are consistent with the fact that about 66% have an Ethical Code. About 50% of the providers who responded are diverse providers (owned by women, minorities and / or employ people with disabilities, social businesses). 71% of the businesses that responded are tiny and small businesses.

This encouraging experience allows us to expand our supplier’s assessments towards next year, including in Hungary.

A Message from LOG’s CEO

Dear reader,

We welcome you to LOG’s first Sustainability report, detailing our commitments, methodologies and performance in Environmental, Social and Governance fields.

The global business landscape, the environmental urgency regarding climate change and our stakeholder’s expectations has led us to document our ESG practices and formulate this report as a tool for constant improvement. During this process, we found out that we must prove our responsibility to our planet, people and communities but also we must promote transparency to all stakeholders.

This report details our efforts to minimize environmental impact related to our operations and products; to strictly maintain the health and safety of all individuals involved in our activities; to provide quality employment and give back to our communities; and to govern and handle all business actions in a proper and ethical manner.

I am proud to share that LOG also joined this year to UNGC’s 10 principles as a signatory company and we will upload a sustainability report once a year. All 10 principles are included in the LOG Code of Ethics.

We wish you a pleasant reading- and welcome any feedback you may have, as part of our commitment to open dialogue and to continuous improvement.

Sincerely yours,

Mr. Shaul Bassi

CEO, LOG Pharma Primary Packaging

LOG serves the pharma industry for more than 50 years, to make its products accessible to the general public with maximum safety, quality and using innovative solutions for maintaining public health. We offer more than 400 packaging solutions, tailored to its clients and market needs. In accordance with this strategy, LOG wishes to continue to address these needs with specific focus on Sustainability.

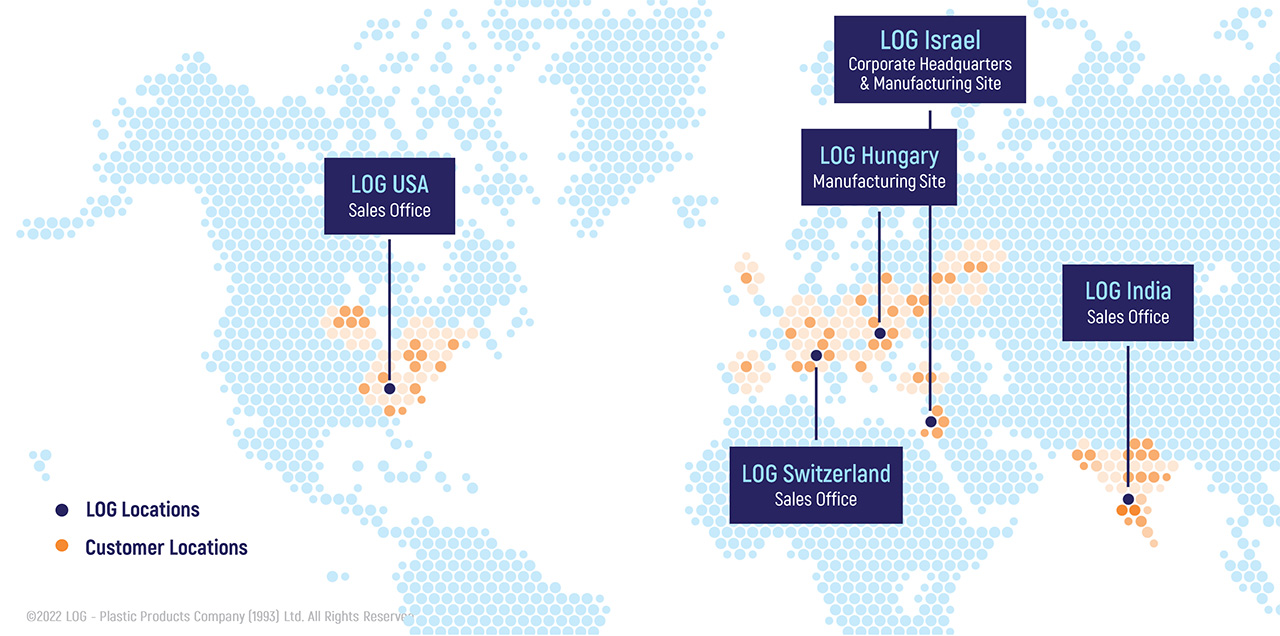

LOG group (Log Holldings) operates in two main locations: in Israel through Log Plastic Products (1993) LTD, which constitutes close to 60% of the group’s total production; And in Hungary through its subsidiary Log Plasticon ZRT. LOG considered a small sized company.

LOG was founded by Kibbutz Ashdot Ya’acov Ichud, Israel, and to this day operates in the same place, many of its employees are kibbutz members and are involved in the life of the local community. In Israel we development and manufacture packaging for pharmaceutical, food and cosmetics industries. In Hungary, we focus on manufacturing packaging only for the pharmaceutical industry.

LOG’s 2021 Sustainability report reflects the current ESG practices and performance and is the first ever-published report.

In order to effectively choose the qualitative and quantitative topics to include in this report, LOG has conducted a benchmark analysis of similar reports by other sector leaders, and has reviewed main requirements arising from reporting frameworks such as GRI, SASB and the U.N. SDGs. We believe the topics included in this report constitute the majority of the material aspects related to our business sector.

This initial report and the data cited in this GRI content index is for the period from 1 January 2021 to 31 December 2021 with reference to the GRI Standards. We aim to constitute and expand the scope of the reported topics, KPIs and policies in the upcoming years, and plan to thoroughly examine the possibility of fully aligning our ESG reports with one or more of the above frameworks.

The report has been prepared with assistance from external ESG specialist consultants. While a certified party has not externally verified the report, we have conducted both internal and third party appropriate checks on the validity of the detailed data, and have reasonable confidence in all published figures and practices. However, as in any document, there may be generalizations, inaccuracies, errors or omissions.

All Forward-Looking Information within this document is based on the company’s current estimates/intentions, but may not materialize due to various reasons.

As part of our commitment to open dialogue, we welcome any feedback or comments from our various stakeholders. We invite our stakeholders to send suggestions and feedback regarding our 2021 Sustainability Report to our HR and ESG VP, Hadas Yafe: ESG@logpac.com

We would like to thank Efrat Musk for the photos from the factory and to Max Molner for the CEO’s photo.